A General Description of a Francis Type Hydroelectric Facility

Use of hydropower peaked in the mid-20th century, but the idea of using water for power generation goes back thousands of years. A hydropower plant is basically an oversized water wheel. Hydropower plants are actually based on a rather simple concept – water flowing through a dam turns a turbine, which turns a generator.

Most hydropower projects use a dam and a reservoir to retain water from a river. When the stored water is released, it passes through and rotates turbines, which spin generators to produce electricity. Water stored in a reservoir can be accessed quickly for use during times when the demand for electricity is high. The following, Figure 1, is a schematic followed by a brief explanation of the components.

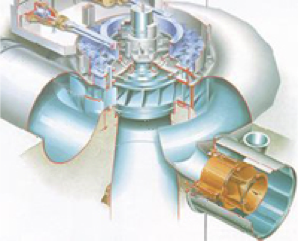

Figure 1 - Schematic of a Hydroelectric Facility

- Dam - Most hydropower plants rely on a dam to hold back water in a large reservoir. Often, this reservoir is used as a recreational lake, as it is the case with Deep Creek Lake.

- Intake - Gates on the dam open and gravity pulls the water through the penstock, a pipeline that leads to the turbine. Water builds up pressure as it flows through this pipe via its speed.

- Penstock - A penstock is a sluice or gate or intake structure that controls water flow, or an enclosed pipe that delivers water to hydraulic turbines. It is a term that has been inherited from the technology of wooden watermills.

- Turbine - The water strikes and turns the large blades of a turbine, which is attached to a generator above it by way of a shaft. The most common type of turbine for hydropower plants is the Francis 5. Turbine, which looks like a big disc with curved blades. A turbine can weigh as much as 172 tons and turn at a rate of 90 revolutions per minute (rpm), according to the Foundation for Water & Energy Education (FWEE).

- Generators - As the turbine blades turn, so do a series of magnets inside the generator. Giant magnets rotate past copper coils, producing alternating current (AC) by moving electrons.

- Transformer - The transformer inside the powerhouse takes the AC and converts it to higher-voltage current.

- Power lines - Out of every power plant come four wires: the three phases of power being produced simultaneously plus a neutral or ground common to all three.

- Outflow - Used water is carried through pipelines, called tailraces, and re-enters the river downstream, here the Youghiogheny river.

The water in the reservoir is considered stored energy. When the gates open, the water flowing through the penstock becomes kinetic energy because it’s in motion. The amount of electricity that is generated is determined by several factors. Two of those factors are the volume of water flow and the amount of hydraulic head. The head refers to the distance between the water surface and the turbines. As the head and flow increase, so does the electricity generated. The head is usually dependent upon the amount of water in the reservoir.

The heart of the hydroelectric power plant is the generator. Most hydropower plants have several of these generators. The Deep Creek Lake facility has two generators built by Allis Chalmers. Each generator can produce 9 MW of electricity when the head, the height between the lake level and the inlet of the turbine, is 440 ft. The flow rate can range from 270 cfs(cubic feet per second) to 330 cfs. The generator spins at 514 rpm. They were installed initially in 1925.

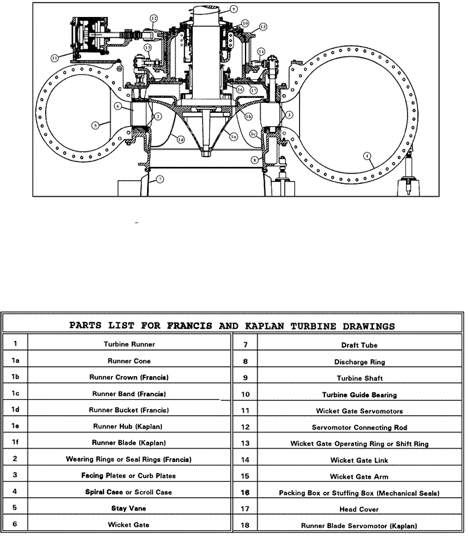

Figure 2 - Cross Section of a Francis Turbine

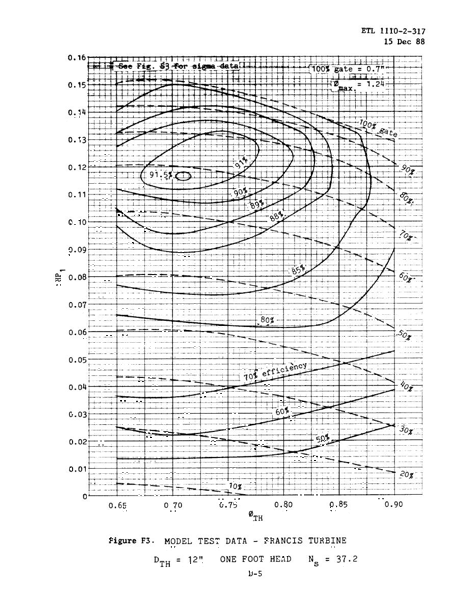

Figure 3 - Performance Curves of a Francis Turbine

- Brookfield acquired the Deep Creek facility in April 2005

- Power generated at the Deep Creek facility is sold to the PJM administered market.

- I appears that workers at the facility are members of the Power Workers Union local 459.

Brookfield sees the current agreement as:

Collaborative Approach to Re-Permitting.

Brookfield entered re-permitting seeking to generally maintain status-quo particularly with respect to important issues of water levels in Deep Creek Lake and releases for the protection of downstream trout fishery. Changes sought in new permit included revised whitewater release schedules and increased operational flexibility to allow expanded participation in the PJM Energy Markets by Brookfield.

Diverse representation and collaboration of public interests between:

Upper Yough Whitewater Coalition consisting of:

- American Whitewater

- American Canoe Association

- Commercial Whitewater Rafting Outfitters led by Precision Rafting

- Team Friendsville - Mayor and Town Council, Town of Friendsville

- Deep Creek Lake Policy and Review Board

- Property Owners Association of Deep Creek Lake, Inc.

- Maryland Department of Environment

- Maryland Department of Natural Resources

- Trout Unlimited (local and regional chapters)

- Local land owners and other interested parties

Brookfield sees its benefits as:

Balanced Outcome.

The new permit provides substantial and balanced improvements to both power and non-power resources Provides improved whitewater release schedule, improved fishing opportunities, better protection of downstream fishery resources and additional operational flexibility; all achieved with no change to the existing Deep Creek Lake rule bands. The improved whitewater schedule is expected to be long term economic driver for downstream interests and municipalities. Brookfield has achieved greater operational flexibility to the benefit of Brookfield and its shareholders.

Highlights of Improved Whitewater Release Schedule.

Prior permit allowed for 59 whitewater release days between April and October, distribution not optimized for either fishing or whitewater interests. New permit provides 64 release days, distribution optimized to provide releases every Saturday from mid- June to mid-September. Outcome is better fishing opportunities during the earlier part of the season and better whitewater opportunities in the heart of the whitewater season – when it matters most for each Releases days over Memorial Day weekend alternate every other year to provide equal benefit to fishing and whitewater interests. The ability to moderately regulate generation (vary flow) during whitewater release now allows Brookfield to better participate in PJM’s ancillary services markets.

In Closing… The Deep Creek agreement is supported by a wide array of public and private interests, maintains the status quo for lake levels, increases recreational fishing and whitewater opportunities and expands operational flexibility for continued clean, renewable domestic power generation.

When the facility was purchase by Brookfield, Stone & Webster, an engineering firm, did a detailed independent REMA review of projects being purchased, including the the Deep Creek Hydro project. The following is from their review of the Deep Creek facility.

Deep Creek Station (“Deep Creek”) is located on Deep Creek Lake in Garrett County, Maryland on 467 acres. The powerhouse has two hydro turbine generators with an average capacity of 18 MW. These generators were placed in service in 1925. Deep Creek has three major components: a dam and reservoir, a water conduit system and a powerhouse with two turbine-generator units and associated equipment. The reservoir has a normal water elevation of 2,461 ft and is impounded by an earth-fill dam with a crest elevation of 2,475 ft. The dam contains a concrete core wall with a top elevation at 2,467 ft. A long overflow weir at the right abutment of the dam, oriented perpendicular to the dam axis serves as the flood discharge control structure. Water that flows over this weir passes over a secondary weir located downstream from the primary weir and then into the natural channel downstream. The following table summarizes the plant characteristics.

| DEEP CREEK CHARACTERISTICS SUMMARY | ||

|---|---|---|

| ITEM | UNIT 1 | UNIT 2 |

| HYDROELECTRIC TURBINE | ||

| Manufacturer | Allis-Chalmers | Allis-Chalmers |

| Type | Francis-type | Francis-type |

| Commissioned (year) | 1925 | 1925 |

| Capacity (MW) | 9 | 9 |

| MISCELLANEOUS | ||

| Penstocks | Dam includes two penstocks | |

| Dam | Earth and rockfill dam | |

| Water conduit | Includes a power intake with vertical slide gate, horseshoe tunnel, and surge tank, Johnson-type inlet valve, and a labyrinth overflow weir in the tailrace channel for aeration |

Starting time, from standstill, was given as 10 minutes. The limitation here is that there is only one synchronizer. Loading time, from synchronous condensing, was given as 1 minute. Station personnel advised that there was no regulatory restriction on starting time but that there was a restriction on the shutdown rate. That restriction is intended to keep the fish from being left high-and-dry in the river downstream from the plant.

3.3.2 DEEP CREEK Deep Creek operates in a peaking mode whenever there is insufficient water for full time operation at full load. Historical and projected average annual energy outputs, representative capacities, and indicated capacity factors are included in the following table. The projected performance is shown for the period 2000 through 2020 and is a combination of inputs and outputs from the Hagler Bailly market analysis model. The market forecast was extended by using the 2020 results through the projected retirement date. Stone & Webster has reviewed the key technical inputs from this model and found them to be reasonable.

| DEEP CREEK HISTORICAL AND PROJECTED PERFORMANCE | ||

|---|---|---|

| PROJECTED UNIT AVERAGE | HISTORICAL | (2000-2020) |

| Average Annual Energy(1), (MWh) | 28,507 | 22,717 |

| Capacity, (MW) | 19 | 19 |

| Capacity Factor, (%) | 17 | 13.89 |

(1) Since station start-up in the 1920’s

Stations that operate in a peaking mode and have storage capacity typically have low capacity factors. The capacity factors given for Deep Creek clearly illustrate the peaking nature of this station. The capacity factor for Deep Creek is 17% and is projected to be approximately 14% over the next 20 years. Deep Creek has a long historical generation record of about 75 years upon which future average generation may be based. Maryland Department of Natural Resources (“DNR”) has recently required a flow release as necessary to maintain a continuous flow of at least 40 cfs in the Youghiogheny River, downstream from the plant to maintain a 25 degrees C temperature in the river at that point during the months of June, July, and August. Deep Creek concentrates the available water into the peak hours. The long-term historical average output is given above as about 28,507 MWh per year. A value of 22,720 MWh would be a reasonable estimate for the average annual output under the postulated conditions. Hagler Bailly has projected a unit average over 20 years of approximately 22,717 MWh per year, which is considered to be reasonable. Stone & Webster used the 2020 market forecast result of 22,720 MWh through the projected retirement date. Deep Creek’s DNR Permit expires on January 1, 2006 and the project must apply for a new permit. The repermitting process includes consultation with all stakeholders interested in the plant operation and the effect of its operation on the environment. The interests of these stakeholders are taken into consideration by the DNR as it reviews the permit application and sets conditions for the term of the new permit. These conditions may include the same conditions or different operational parameters than are included in the current license.

4.1.12 DEEP CREEK STATION

CIVIL STRUCTURES

The structures at Deep Creek appear to be in very good condition, to the extent that these items were visible. Deep Creek has an earth fill dam with a long overflow weir at the right-bank. We understand that considerable remedial work was performed in the recent past and that the present condition requires only normal O&M. The dam and associated structures appear to be in excellent condition during the site visit. Station personnel advised that there had been only three minor incidents of spillage in the history of the plant. That statistic suggests that the turbine capacity is quite high relative to the potential for flood formation.

MECHANICAL EQUIPMENT

The equipment at Deep Creek appears to be in very good condition, to the extent that these items were visible. Station personnel advised that the turbine runners were replaced, in 1972 and 1973, with new runners made of steel with stainless steel overlay. A brief review of the parameters suggests that the available diameter would support a further capacity increase but the tail water level does not appear to provide cavitation protection for the existing capacity. A capacity increase would serve only to shift more energy from off-peak to on-peak. There would be no increase in total energy because of the almost complete absence of spillage.

ELECTRICAL AND CONTROLS

The electrical equipment is maintained in good condition and the generating units appeared to be operating satisfactorily.

| REMAINING LIFE | OF THE FACILITIES | AS PROJECTED | BY REMA |

|---|---|---|---|

| STATION | AGE AS OF JANUARY 1, 2000 | ESTIMATED RETIREMENT DATE | REMAINING LIFE |

| Hydroelectric Stations | |||

| Deep Creek | 77 | 2029 | 30 years |

Hydroelectric stations typically have long lives because their major components are civil structures. With proper maintenance, the structures at Piney and Deep Creek should remain useable over the life projected by REMA. Individual equipment items may continue to need replacement from time to time as part of the ongoing maintenance effort.

The only environmental issues associated with Piney and Deep Creek include secondary containment for the lube oil tanks and emergency batteries and petroleum hydrocarbon contaminated soil at Piney. The extent of the contamination has not yet been determined. There are no sources of air pollution at either station as there are no combustion sources.

DEEP CREEK

Although Deep Creek was originally licensed by FERC, FERC notified the Maryland Water Resources Administration by letter dated January 11, 1994 that the project was no longer under FERC jurisdiction. Deep Creek presently operates under a State of Maryland DNR Water Appropriations Permit Number GA92S009 (02). This permit was issued on October 1, 1999 and expires on January 1, 2006. Deep Creek personnel advised that the DNR plans to transfer this permit to REMA without change to the conditions or the expiration date. At the expiration, the operating conditions stipulated by the permit would be subject to revision.

6.3.12 DEEP CREEK

STAFFING

Deep Creek has a staff of two full-time people, with an off-site superintendent at Seward. This staffing level represents a reduction from three full-time people in 1997 and from four full-time people in 1995. Supplementary staffing has been provided by temporary employees.

OPERATION AND MAINTENANCE AND CAPITAL EXPENSES

Deep Creek personnel provided the following data on historical expenditures for O&M.

| HISTORICAL | O&M EXPENSES |

|---|---|

| YEAR | EXPENSES |

| 1997 | $506,000 |

| 1998 | $501,000 |

| 1999 | $351,000 |

REMA’s projected labor, other O&M, and capital expenses are shown in the following table.

PROJECTED O&M EXPENSES

YEAR O&M CAPITAL TOTAL 2000 $ 450,000 $ 95,000 $ 545,000 :—–: :—— :—– ——: 2001 $ 450,000 $ 600,000 $1,050,000 2002 $ 450,000 $ 0 $ 450,000 2003 $ 450,000 $ 600,000 $1,050,000 2004 $ 450,000 $ 450,000 $ 900,000

The O&M costs for the year 2000 include $250,000 for OCB replacement that has already been completed. The O&M costs for 2001 include $150,000 for voltage regulator upgrade. The budget provided appears to be reasonable. In Stone & Webster’s opinion, the assumed level of capital and overhaul expenses included in the detailed forecast are adequate to keep the station operating reliably through the projected retirement date.

OVERHAUL SCHEDULE

Deep Creek appears to be maintained in very good operational condition based on the observations made during our site visit. The following maintenance activities are scheduled for the next five years:

- 2001 Two week clean-up inspection

- 2002 Two week clean-up inspection

- 2003 Three week internal inspection/unit

- 2004 Two week clean-up inspection

- 2005 Two week clean-up inspection

MAINTENANCE MANAGEMENT

REMA will convert the maintenance management to the SAP America system as discussed in section 6.3.3. It is considered to be an acceptable maintenance tracking system in the industry.

- Deeds from Penelec to Sithe Maryland Holdings LLC (for Deep Creek), dated as of November 19, 1999

- Easement and License Agreements between Penelec and Sithe Maryland Holdings LLC (for Deep Creek), dated as of November 19, 1999

- Deep Creek Hydroelectric Generating Station Former Williamsburg Generating Station Keystone Generating Station

- Deep Creek Hydroelectric Generating Station East Flemington Substation

PROPERTY TYPE OF AGREEMENT PARTY PURPOSE Deep Creek easement 1/31/91 Site, Douglas et ux. Right-of-way Deep Creek easement 5/31/39 Potomac Edison Co. Lines and wires (Sang Run #6) Deep Creek easement 9/13/90 Legacy Homes Corp. 2 storm water discharges Deep Creek grant Maybury, Robert H. et. al. Privilege for 30’ roadway Deep Creek lease 9/22/97 Helbig, Jacob Premises at 141 Mayhew Inn Road Deep Creek lease 6/13/91 Elston, Thomas N. et.al. 3 lots Deep Creek Co-Insurance Schedule delivered 11/24/99 Lawyers Title Corporation and Stewart Title Insurance Company Co-Insurance Schedule and Endorsement for Deep Creek owner’s title policy

OUTAGES STATION DESCRIPTION DATE LENGTH Deep Creek Unit 1-Oil Circuit, Breakers, Annual Inspection 01/10/00-01/21/00 2 weeks Deep Creek Unit 25-Oil Circuit, Breakers, Annual Inspection 01/24/00-02/04/00 2 weeks

7.4 Transmission Operating Requirements

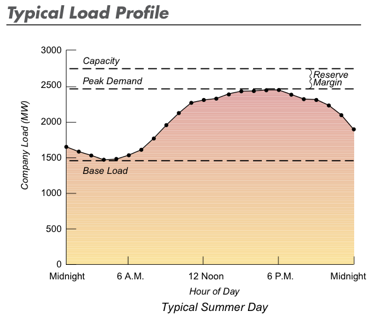

Figure 4 - Typical Load Profile.

7.4.1 System Restoration: Deep Creek Station can supply black start energy to the 115 kV transmission system. In the event that a system-wide blackout occurs, the station may be called upon to provide an initial source of energy for the restoration of the Company and regional transmission systems. When requested, the Producer will start the generating units and coordinate their operation with the Transmission Operators.

On April 27, 2005, the Company completed the acquisition of two hydroelectric generating facilities, Piney and Deep Creek, with a total of 48 megawatts of capacity from Reliant Energy Inc. for cash consideration of US $42 million. The Piney station is a 28 megawatt facility located on the Clarion River in Pennsylvania and the Deep Creek station is a 20 megawatt facility located on the Youghiogheny River in Maryland.

The above graph is for Maryland.

Brookfield Renewable Power Inc. was formed as the result of the amalgamation of Brookfield Power Inc. and Brookfield Power Corporation in May 2008. It is wholly owned by Brookfield Asset Management. Brookfield Renewable Power Inc.’s primary business is renewable power generation. Some of its generation assets are owned through Brookfield Renewable Power Fund.

Brookfield Renewable Power Inc., wholly-owned by Brookfield Asset Management Inc., has more than 100 years of experience as an owner, operator and developer of hydroelectric power facilities. Its total portfolio includes more than 170 generating facilities with over 4,200 megawatts of capacity including Prince Wind, one of the country’s largest wind installations. It also has a significant hydroelectric and wind project pipeline. Brookfield Renewable Power’s operations are primarily located in North America and Brazil. Brookfield Asset Management Inc., focused on property, power and infrastructure assets, has over US$100 billion of assets under management and is listed on the New York and Toronto Stock Exchanges under the symbols BAM and BAM.A, respectively, and on Euronext Amsterdam under the symbol BAMA. For more information, please visit Brookfield Renewable Power’s website at www.brookfieldpower.com and Brookfield Asset Management’s website at www.brookfield.com.

References:

- RELIANT ENERGY MID ATLANTIC POWER HOLDINGS LLC (Form: S-4, Received: 12/08/2000 08:05:20)

- RELIANT ENERGY MID ATLANTIC POWER HOLDINGS LLC - 424B3 - 20010220 - NOTES_TO_FINANCIAL_STATEMENT

The following is from an article in the Mountain Lake Quarterly.

Deep Creek Lake lies just west of the Allegheny Front on a large plateau known as the Tablelands or Allegany Highlands. Its location at the southernmost end of Meadow Mountain places it west of the Eastern Continental Divide and within the Mississippi River watershed. It gets its name from Deep Creek, and was a a hydroelectric project constructed in the 1920 by the Youghiogheny Hydroelectric Company. Deep Creek Dam, located about 8 miles (13 km) north of Oakland, Maryland, consists of an earth and rock wall dam across a tributary of the Youghiogheny River. Construction of the dam began in 1923 and was completed in 1925. Man has been associated with the use of this land for thousands of years. Early nomadic hunters and gatherers, followed by Native American hunters, roamed through the mountains of Garrett County but have left little record of their presence. Beginning in the 1700’s, early settlers to the region eked a subsistence existence based on the utilization of the area’s abundant natural resources. The mountains remained relatively untouched until the turn of the century when massive logging operations began stripping the land of the virgin Red Spruce, Hemlock, White Pine, and Yellow Birch forests.

Much of the area consists of a forest that has regenerated from the original stands of timber and has become an excellent example of a maturing northern hardwood forest. Oaks and hickories are now the dominant species. Forest wildlife species such as black bear, wild turkey, bobcat, and white tailed deer have grown in numbers over the past decades as habitat has been preserved and managed. Small mammals such as squirrel, chipmunk, raccoon, skunk, and opossum are frequently seen. The area is also home to numerous plant species, some rare, found on the forest floor. The Tableland’s weather is quite unique for the region. Many winters bring over 200 inches of snow and the greening of leafing trees does not occur until mid May. Summers are characterized by warm days and cool nights. Autumn comes alive with blasts of color in early to mid October with clear, crisp days and cold evenings. Coal was soon discovered which established the Brant coal mine which produced bituminous coal that was used by the local community for heating and blacksmith work.

Over eighty years ago, the idea was conceived to harness the water powers of the Youghiogheny (pronounced “yock-a-gain-ee” or locally referred to at the “yock”) River, Maryland’s only designated “wild” river and Deep Creek, a tranquil stream situated between Roman Nose Ridge and Marsh Hill Ridge, for the production of electricity. Planning began as early as 1908 but early attempts fell through. In 1921 the Youghiogheny Hydro-Electric Corporation was granted the right to construct dams across Deep Creek and the Youghiogheny River, a subsidiary of the Pennsylvania Electric Corporation (PENELEC). Preliminary surveys were conducted in 1922 to determine the water power possibilities by measuring the running levels of the Youghiogheny River and establishing gauging stations to determine the amount of water flow. The concept that resulted from these surveys proposed the construction of four dams and three power houses. One of the dams would be located near the confluence of Deep Creek and the Yough, another in the Yough north of Deep Creek, and 2 dams south of the Deep Creek project. Because it would be financially self sufficient, feasibility studies showed that the Deep Creek dam and powerhouse should be completed first. In the end, it was the only dam from the original concept to be constructed. As the project began in November of 1923, the first step was the acquisition of land. The Eastern Land Corporation was licensed by the state to handle the real estate transactions. The price per acre ranged from $5.00 to $2,500, with an average cost of about $55.00. Entire farms were purchased even when just a portion of the land would be flooded. Many farms were purchased not because they would be flooded but because the roads leading to them would be cut off by the rising water. In total, about 140 farms were purchased to make up the 8,000 acres acquired for the project, with only 4500 acres actually inundated. When possible, buildings were moved to higher ground including private homes and 2 school houses. The dam and powerhouse were built by Mr. Charles Hawley & Company, Inc., of Washington, DC. The 1,000 men employed for the purpose of construction were housed in 2 large buildings close to the location of what is now Red Run Lodge. Various other projects resulted from the construction process including: connecting the B&O Railroad at Oakland and extending it to the dam and power sites, relocation of nearly 15 miles of highway, relocation of 2 steel bridges, the opening of a quarry to prepare stone for the dam and roadways. Taking almost 2 years to complete, the plant opened for operation at 4 p.m. May 26th, 1925. Eighty years later, the earth and rock fill dam remains much as it was then. It is about 1,340 feet long and crosses Deep Creek about 1.75 miles upstream from its confluence with the Yough. Water from the lake is transported to the powerhouse through a 7,000 foot power tunnel. The brick powerhouse is capable of producing about 18 megawatts of electric power with its 2 Francis type turbines and 2 generators. Both of the original steel bridges have been replaced with more modern concrete structures. As word spread about the fishing and boating opportunities during the 1950’s and 60’s, the area saw more visitors from Pittsburgh. In the 1980’s, with the opening of Interstate highways from the East, an increased number of visitors came from the Baltimore/Washington population centers. Today Deep Creek Lake is owned by the state of Maryland and managed by the Department of Natural Resources. Holding the title of Maryland’s largest freshwater lake, it is 13 miles long with 65 miles of shoreline and covers about 3,900 acres. With an average depth of about 25 feet, maximum depth reaches about 75 feet near the breast area of the dam. A fortunate by-product of man’s need to generate power, the resulting natural beauty of Deep Creek Lake cannot be denied.

PLV

First Published: 8/20/2012